Growing interest in façade materials has encouraged many construction planners to take a closer look at how an ACP Line works alongside broader Aluminum Composite Material Engineering. This combination has become more relevant as designers explore new shapes, textures, and colors for exterior and interior projects. While structural requirements remain a priority, advancements in processing methods are creating new opportunities for both performance and appearance across modern building applications.

Refining Surface Coating Stability Through Improved Coil Coating Systems

One area where innovation is becoming noticeable is the treatment of aluminum coils before they enter panel lamination. The coating line—featuring cleaning, passivation, rolling-coater application, and controlled baking—now supports steadier film formation. Rolling coaters help keep coating thickness uniform, which is important when panels are used for curtain walls, ceilings, or interior partitions where slight irregularities can affect installation or visual alignment.

The ability to work with PVDF, PE, or AC coatings allows engineering teams to match the surface layer with project environments. PVDF tends to be selected for outdoor applications requiring longer-term color stability, while PE or AC can suit indoor uses. Heating and drying systems powered by natural gas or diesel oil provide consistent curing conditions, helping panels maintain the expected surface quality once they reach shaping or bending stages.

These enhancements in pre-lamination coating processes contribute to more predictable panel performance during routing, folding, or cassette fabrication. It gives installers a more stable foundation to work with, especially when project timelines require steady material output without frequent adjustments.

Applying Three-Dimensional Metal Plate Concepts to ACP Production

Three-dimensional metal plates have introduced more variety into architectural surfaces, and some design principles behind them are influencing ACP Line development. The 3D plates—known for corrosion resistance, weathering tolerance, and decorative impact—use stamping and stretching to create textured surfaces. These processes highlight the demand for equipment capable of handling deeper surface features without compromising structural stability.

As ACP lines continue adapting, more attention is placed on achieving consistent aluminum surface conditions before lamination. Uniform tension and precise control of aluminum strip flatness help ensure that bonded layers accommodate patterned or textured concepts introduced later in the fabrication process. This makes it easier for manufacturers to produce ACP panels compatible with curved surfaces, raised patterns, or combinations of flat and embossed areas.

The growing interest in custom color palettes—ranging from metallic tones to multi-layer finishes—also aligns with what the three-dimensional metal plate segment is offering. Improved coating modules support a wider range of tones without requiring large batch sizes, which expands design flexibility without sacrificing process consistency.

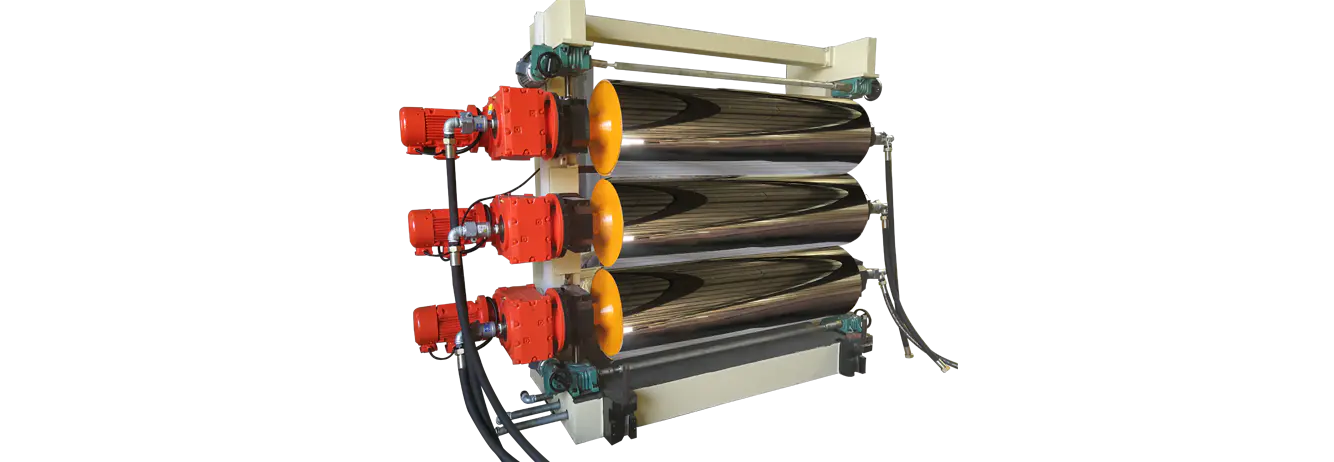

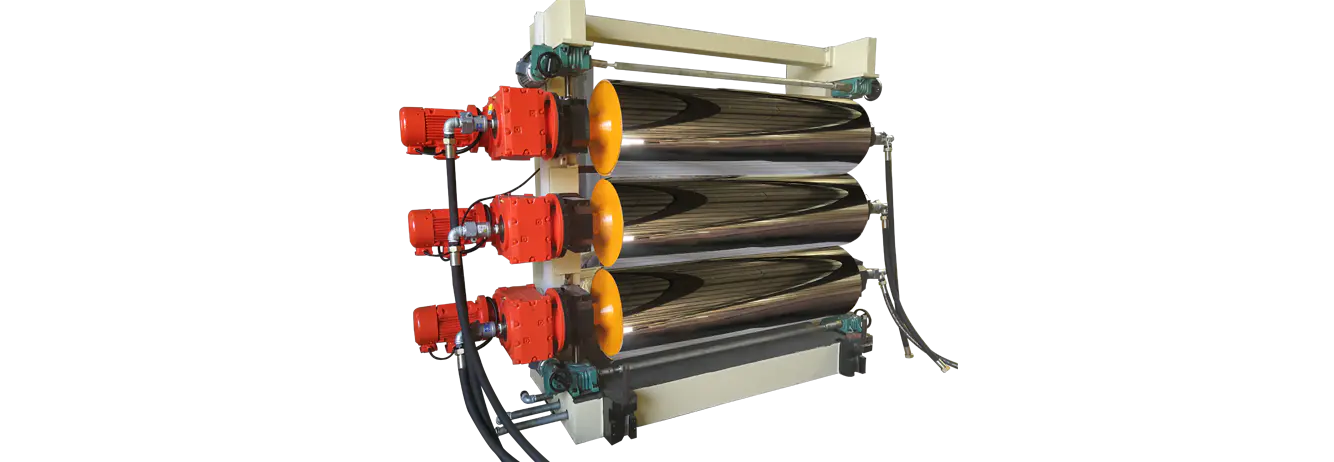

Increasing Stability of Core-Layer Bonding Through Enhanced Lamination Control

Bonding remains a central component of Aluminum Composite Material Engineering, and newer ACP Line configurations are focusing on controllable lamination pressure and temperature zones. A more stable thermal environment during bonding helps reduce internal stress variations, which can influence how panels behave under wind load, temperature changes, or bending during installation.

Advanced lamination modules monitor core density and adhesion levels across the entire width—whether panels are produced at 800 mm, 1300 mm, or beyond 1600 mm. This is particularly useful for large-format panels used on expansive façades, where even minor inconsistencies can affect alignment across floors or structural frames.

These improvements also help prevent issues such as unwanted curvature, corner cracking, or uneven bending performance during cassette-panel fabrication. Predictable bonding behavior supports safer installation practices and helps maintain joint accuracy across large surfaces.

Integrating Multi-Module PLC Systems for Better Line Coordination

ACP fabrication requires several stages—uncoiling, surface cleaning, coating, lamination, cutting, and packaging. Multi-module PLC systems have become more common in coordinating these steps. Instead of operating each segment as a separate unit, integrated controls help synchronize tension, temperature, and speed to maintain uniformity across the production run.

With PLC supervision, operators can adjust production speed—often ranging between 0–6 m/min—based on material characteristics or coating types. When aluminum thickness, coil hardness, or core material is changed, the line can be recalibrated with fewer manual interventions. This steady transition reduces the likelihood of panel inconsistencies that typically arise when switching between batches or formats.

中文简体

中文简体 English

English Português

Português русский

русский Español

Español عربى

عربى