Achieving consistent quality on a coil coating line requires careful attention to both the process and the equipment used. Operators working with aluminum composite panel equipment need to manage material preparation, coating application, and mechanical conditions to support stable production. Understanding practical techniques helps maintain uniform surface finish, reduces defects, and supports overall workflow.

Proper Coil Handling and Preparation

The quality of the final panels begins with proper handling of raw aluminum coils. Operators should inspect coils for scratches, rust, or oil residues and remove any contaminants before processing. Correct alignment and careful loading reduce the risk of damage to the equipment and material.

Control of Coating Material

Maintaining uniform coating characteristics is essential for surface quality. Operators should monitor coating viscosity, temperature, and feed rates regularly. Ensuring that coating heads and rollers are clean and free of blockages prevents uneven application. Adjustments should be made gradually to maintain consistency, avoiding abrupt changes that could create streaks or irregular thickness on the aluminum panels.

Monitoring Line Speed and Tension

Mechanical factors such as line speed and strip tension influence the evenness of the coating. Operators should adjust these parameters according to coil thickness and material properties. Sudden variations in speed or tension can result in wrinkles, stretching, or misalignment. Careful control helps maintain uniform coating thickness and reduces mechanical stress on the aluminum composite panel equipment.

Temperature and Curing Management

Even heating during the curing process is important for stable surface properties. Operators should monitor oven temperatures, airflow, and thermocouple readings across the line. Uneven curing can result in color variation, surface defects, or incomplete drying.

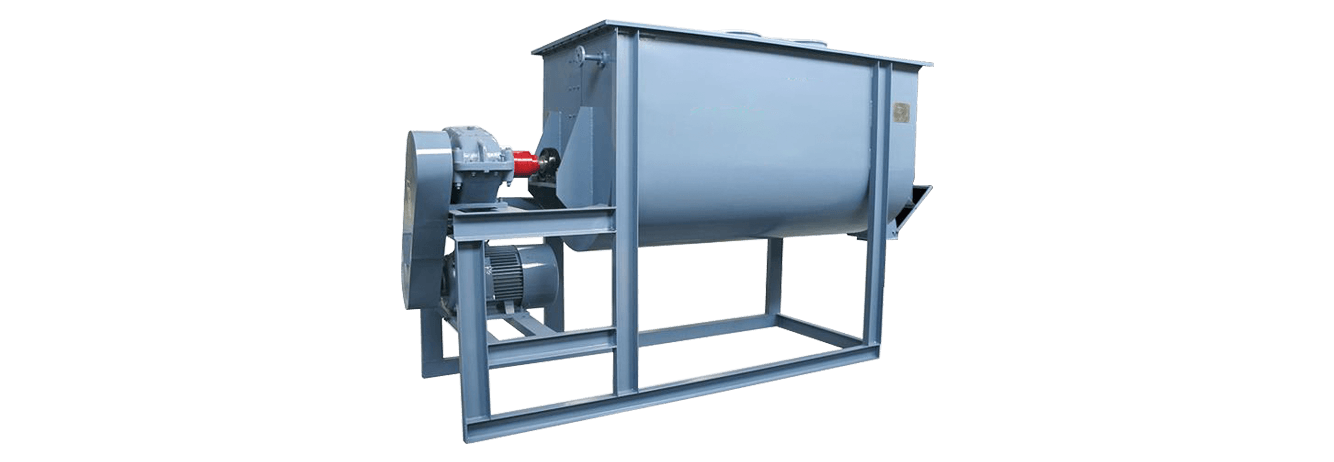

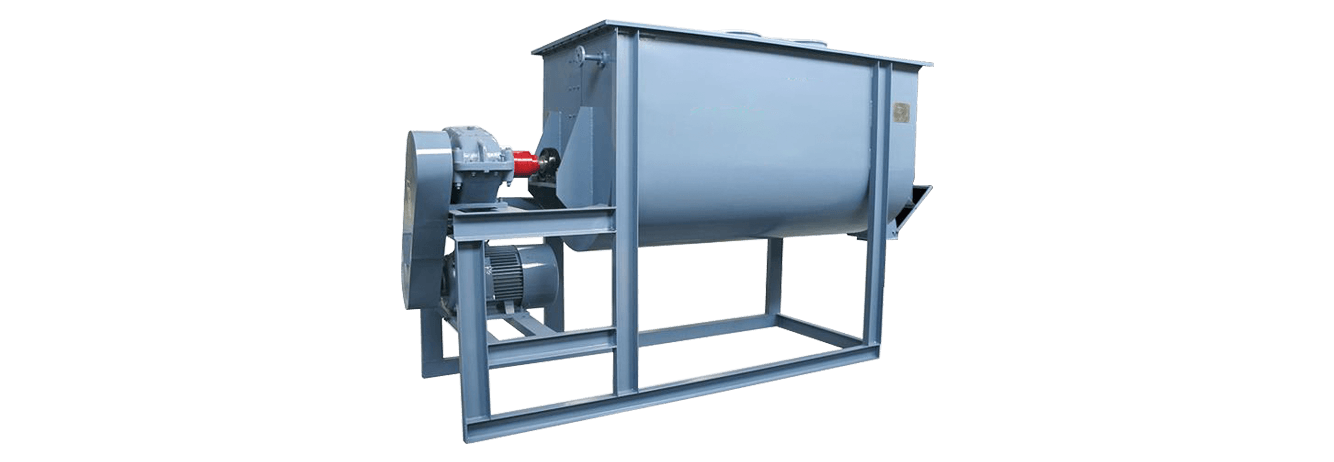

Regular Equipment Maintenance

Routine inspection and maintenance of aluminum composite panel equipment contribute to stable output quality. Bearings, rollers, and drive components should be lubricated and checked for wear. Electrical systems, sensors, and control units require calibration and testing to ensure accurate operation. Addressing mechanical and electrical issues proactively helps maintain consistent production without sudden interruptions.

Environmental Considerations

Environmental conditions in the production area can affect coating performance. Operators should monitor humidity, dust, and temperature levels. Stable conditions reduce the likelihood of surface contamination or material deformation. Proper ventilation and filtration help maintain a clean workspace, supporting the consistency of the coil coating line.

Operator Training and Standard Procedures

Skilled operators play a key role in maintaining output quality. Training on machinery operation, coating techniques, and emergency procedures ensures that handling is consistent and informed. Standard operating procedures for start-up, production, and shutdown provide a clear framework for daily operations. Following established practices reduces variability and supports uniform production.

Monitoring Output and Quality Checks

Consistent quality requires ongoing observation and inspection of the finished panels. Operators can use visual checks or automated measurement systems to detect coating thickness variations, surface texture issues, or color inconsistencies. Recording production data and analyzing trends helps identify deviations early, allowing adjustments before defects propagate across the batch.

Workflow Coordination Across Line Sections

Effective coordination between the unwinding, coating, curing, and winding sections supports steady output. Clear communication and synchronized adjustments between sections reduce sudden mechanical stresses and prevent material handling issues. Well-coordinated workflow allows the aluminum composite panel equipment to operate under stable conditions, which contributes to consistent quality throughout production.

中文简体

中文简体 English

English Português

Português русский

русский Español

Español عربى

عربى