Maintaining aluminum composite panel equipment is essential for the continuous operation of a coil coating line. Operators who focus on proper handling, routine maintenance, and careful monitoring can support longer equipment service life while reducing interruptions in production. Understanding practical steps to care for the machinery helps maintain operational stability and supports consistent output quality.

Regular Inspection of Mechanical Component

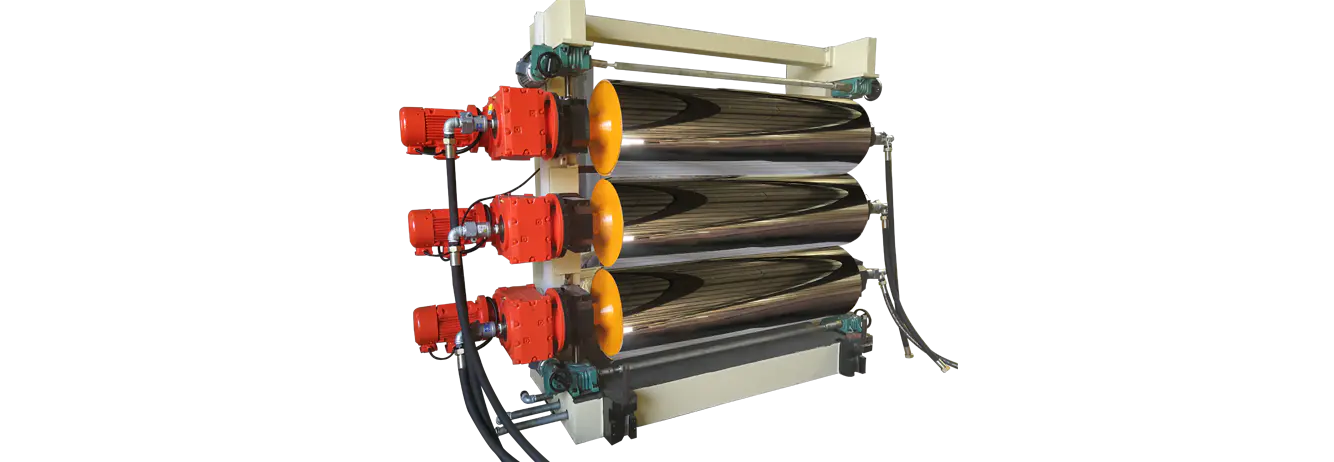

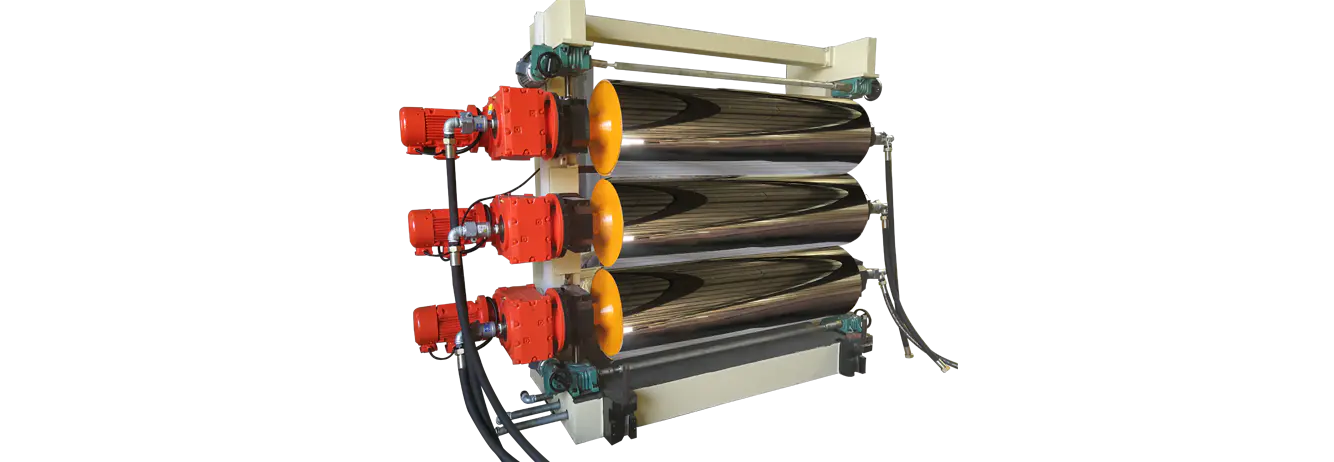

Frequent inspection of moving parts such as rollers, bearings, and drive mechanisms is an important practice. Operators should check for signs of wear, misalignment, or unusual noise. Lubrication schedules should be followed according to manufacturer guidelines, and worn components should be replaced in a timely manner. Keeping mechanical parts in good condition reduces stress on the system and supports continuous operation.

Maintaining Electrical and Control Systems

Electrical panels, sensors, and control units form the backbone of aluminum composite panel equipment. Operators should ensure that connections are secure, wiring is intact, and control systems are functioning as expected. Periodic calibration of sensors and verification of automation settings help prevent unexpected interruptions. Monitoring electrical components also aids in early identification of potential issues before they affect the coil coating line.

Coil Handling and Preparation

Proper handling of raw aluminum coils is a key factor in extending equipment lifespan. Operators should avoid sudden impacts or improper loading that can damage the machinery. Cleaning coils and removing surface contaminants before processing reduces the risk of scratches and defects that could affect rollers or coating heads. Careful preparation also contributes to more consistent coating application and reduces strain on the equipment.

Managing Line Speed and Tension

Adjusting line speed and strip tension according to material properties is necessary to maintain smooth operation. Excessive tension or sudden changes in speed can place stress on rollers, motors, and other moving parts. Operators should monitor the line continuously and make gradual adjustments as needed. Maintaining controlled tension and speed helps prevent mechanical wear and prolongs the service life of the aluminum composite panel equipment.

Monitoring Coating Application

Consistent application of coating materials reduces the chance of uneven stress on the line. Operators should check coating thickness, feed rates, and roller conditions regularly. Ensuring that coating heads are free from blockage or buildup prevents additional strain on mechanical components. Maintaining stable coating conditions contributes to uniform product quality and less mechanical disturbance.

Routine Cleaning and Environmental Care

Dust, residue, and debris can accumulate on machinery and interfere with performance over time. Regular cleaning of the line, including conveyor surfaces, rollers, and surrounding areas, supports smooth operation. Environmental factors such as temperature and humidity should also be monitored. Stable conditions reduce the likelihood of corrosion, buildup, or material deformation that could affect the equipment.

Preventive Maintenance Scheduling

Creating a preventive maintenance schedule helps operators address potential problems before they disrupt production. Scheduled checks, part replacements, and system calibrations provide a structured approach to equipment care. Recording maintenance activities and monitoring trends allows for informed decisions regarding the timing of interventions and reduces unexpected downtime.

Operator Training and Standard Procedures

Operators play a central role in equipment longevity. Proper training on machinery operation, handling protocols, and emergency procedures ensures consistent handling practices. Clear standard operating procedures for start-up, operation, and shutdown support safe use of aluminum composite panel equipment and contribute to reduced mechanical stress over time.

Monitoring Production Data and Performance

Tracking performance data from the coil coating line can reveal early signs of wear or imbalance. Observing trends in tension, speed, and coating consistency allows operators to adjust settings before issues escalate. Maintaining records of process parameters supports informed operational decisions and provides reference points for future maintenance planning.

Coordinating Workflow Across Sections

Smooth coordination between preparation, coating, curing, and winding sections reduces strain on the line. Operators should communicate changes in material, speed, or coil properties across the workflow.

中文简体

中文简体 English

English Português

Português русский

русский Español

Español عربى

عربى