Across the construction and manufacturing sectors, ACP Line (Aluminum Composite Panel production line) technology plays a key role in producing durable and visually consistent materials for modern architecture. When combined with Coated Aluminum Coil, the process creates panels that are not only lightweight but also capable of maintaining long-term surface stability. As industry demand for efficiency and precision grows, automation has become central to improving both panel quality and production output. Understanding how automated systems enhance these aspects helps manufacturers and engineers better utilize their production capacity while maintaining consistent results.

The Evolving Role of Automation in ACP Production

Automation within ACP production is no longer limited to high-end facilities. As production lines expand, automation allows for continuous, stable, and precise operation. Automated systems address these challenges through real-time monitoring, digital feedback loops, and intelligent control mechanisms.

By integrating advanced automation technologies, ACP Lines can regulate every key process—from aluminum coil unwinding and cleaning to coating, drying, lamination, and cutting. For coated aluminum coils, automated coating and curing systems guarantee stable adhesion and consistent surface finish across batches, ensuring the panels remain uniform once installed on building façades or interior applications.

Precision Control Over Coated Aluminum Coil Processing

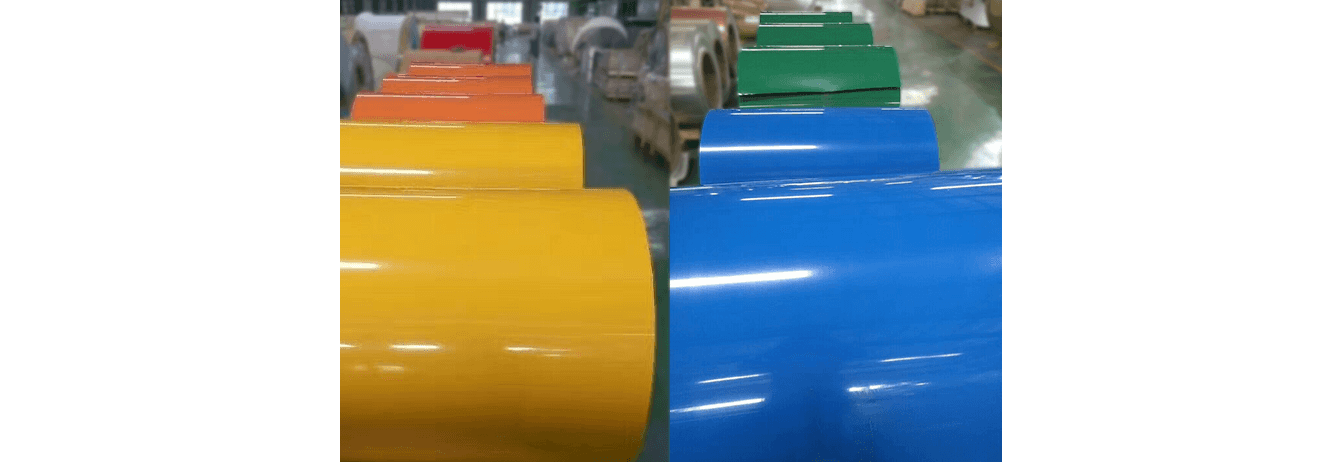

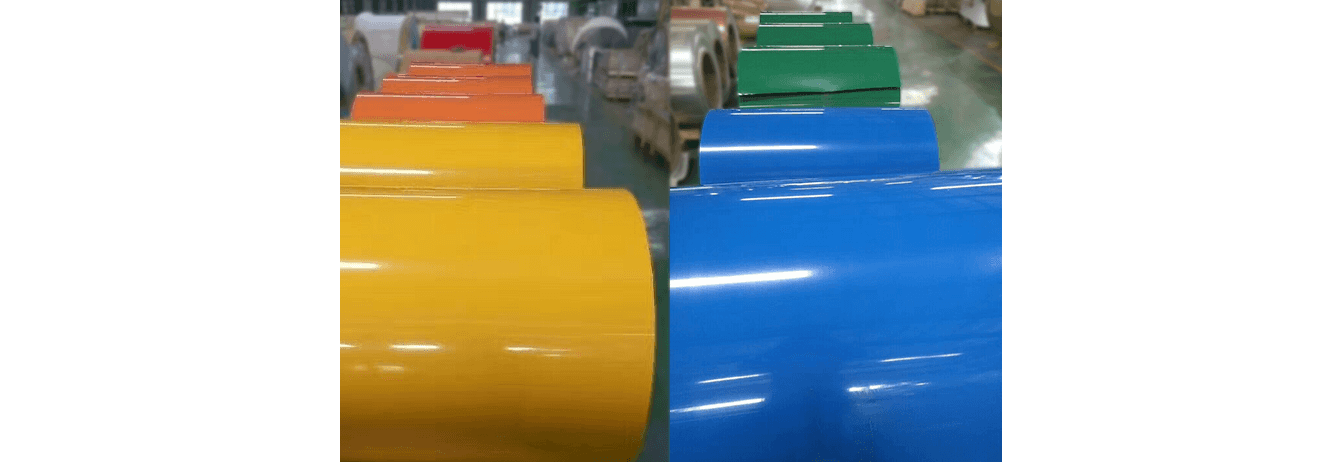

The quality of an aluminum composite panel largely depends on how well the Coated Aluminum Coil is prepared and handled during production. Automation enhances this stage by maintaining accurate line speed, tension control, and coating application parameters. Modern coating machines are equipped with sensors that measure film thickness in real time, allowing for immediate adjustments to prevent uneven coating or color deviation.

This precision ensures that the coating adheres properly to the aluminum substrate, enhancing corrosion resistance and weather durability. Automated drying and curing systems also ensure consistent temperature profiles, preventing surface defects such as blistering or uneven gloss. Together, these controls extend the lifespan of the coated surface while preserving its aesthetic appeal under varied environmental conditions.

In addition, automated coil feeding and cutting units streamline material handling, preventing scratches or deformation that can occur during manual transfer. This contributes directly to higher-quality finished panels and reduces waste from reprocessing.

Enhanced Efficiency Through Continuous Production

Automated feeding systems synchronize coil movement with coating and lamination stages, ensuring stable output rates. Production lines can operate at optimized speeds while maintaining consistent coating and bonding performance.

This continuous operation reduces downtime associated with manual adjustments or material setup. Automated control systems also help operators track energy consumption, raw material usage, and maintenance needs. The result is a more predictable and efficient production schedule, allowing manufacturers to meet tight project deadlines without compromising product quality.

Consistent Lamination and Bonding Performance

The lamination stage is critical in ensuring the structural integrity of composite panels. Automation enhances precision in temperature and pressure control during bonding between the coated aluminum sheets and the polymer core. Advanced temperature sensors and automatic pressure regulators maintain stable lamination conditions, reducing the risk of delamination or air entrapment.

Automated laminators ensure uniform adhesive distribution and exact synchronization between both coil surfaces, resulting in strong, stable bonding across the entire sheet. The outcome is panels with improved mechanical strength and smooth surface appearance, suitable for both interior and exterior construction applications.

As the construction industry moves toward smarter production and sustainable development, the combination of coated aluminum coils and automated ACP Lines represents a practical path forward. Through precise control, data integration, and consistent operation, automation strengthens both production efficiency and product quality—helping the material meet the growing technical and aesthetic demands of modern construction.

中文简体

中文简体 English

English Português

Português русский

русский Español

Español عربى

عربى