Modern architecture is evolving toward efficiency, aesthetics, and sustainability. In this transformation, Aluminum Composite Material Engineering and the use of Aluminum Coil have become essential components of structural and façade innovation. These materials not only contribute to the strength and visual appeal of buildings but also respond to environmental challenges and design flexibility needs that define contemporary construction.

Durability and Lightweight Structure

Aluminum composite materials (ACM) are known for their remarkable balance between strength and lightness. Engineers use multi-layered structures where aluminum sheets are bonded with non-aluminum cores, achieving high rigidity without adding unnecessary weight. This balance makes ACM ideal for large building façades, ceilings, and claddings, reducing the overall load on structural frames. The lightweight characteristic also simplifies transportation and installation, contributing to efficient construction management and cost control.

Additionally, aluminum’s natural resistance to corrosion enhances the longevity of panels and coils exposed to various weather conditions. Even in coastal or industrial environments with high humidity or chemical exposure, well-coated aluminum surfaces maintain their integrity and appearance for years.

Surface Coating and Finishing Technology

The application of aluminum coil coating technology has significantly improved the performance of modern construction materials. Through advanced coating lines, aluminum coils can be treated with PE (polyester) or PVDF (polyvinylidene fluoride) coatings. Each coating type serves a specific purpose: PE coatings offer good color diversity and surface smoothness for indoor or decorative applications, while PVDF coatings provide outstanding resistance to ultraviolet radiation and pollutants, making them suitable for outdoor façades.

These coatings are available in a variety of color options — such as pure white, ivory, silver, champagne, and black — giving designers creative flexibility. The consistent and uniform coating achieved through precision rolling processes ensures that every aluminum surface maintains a stable appearance across large-scale projects.

Energy Efficiency and Sustainability

Sustainability has become a central theme in construction, and aluminum composite material engineering contributes to this goal in several ways. Aluminum is fully recyclable without losing its structural or aesthetic properties. During the recycling process, it consumes significantly less energy compared to primary production, helping reduce the carbon footprint of a building project.

Furthermore, the reflective surface of aluminum panels helps moderate building temperatures by reducing heat absorption. This contributes to better energy performance of the structure, lowering the demand for air conditioning in hot climates and improving overall thermal balance. In modern green building design, such properties play a critical role in achieving energy certification goals and creating comfortable environments for occupants.

Design Versatility in Architecture

The adaptability of aluminum composite materials allows architects to explore diverse forms and surface effects that are difficult to achieve with traditional materials like stone or concrete. The materials can be cut, bent, perforated, or shaped into complex designs while maintaining a clean and elegant finish.

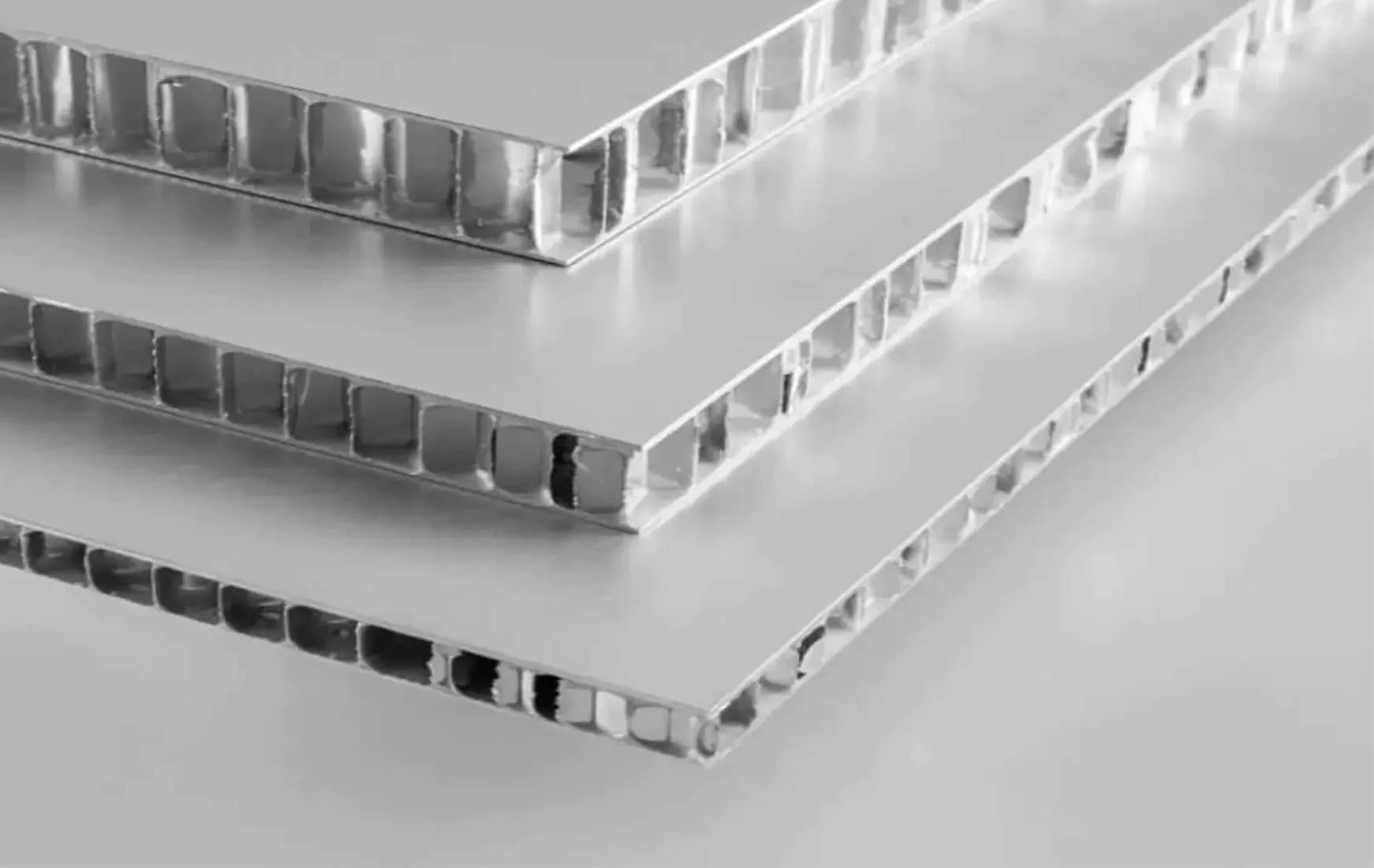

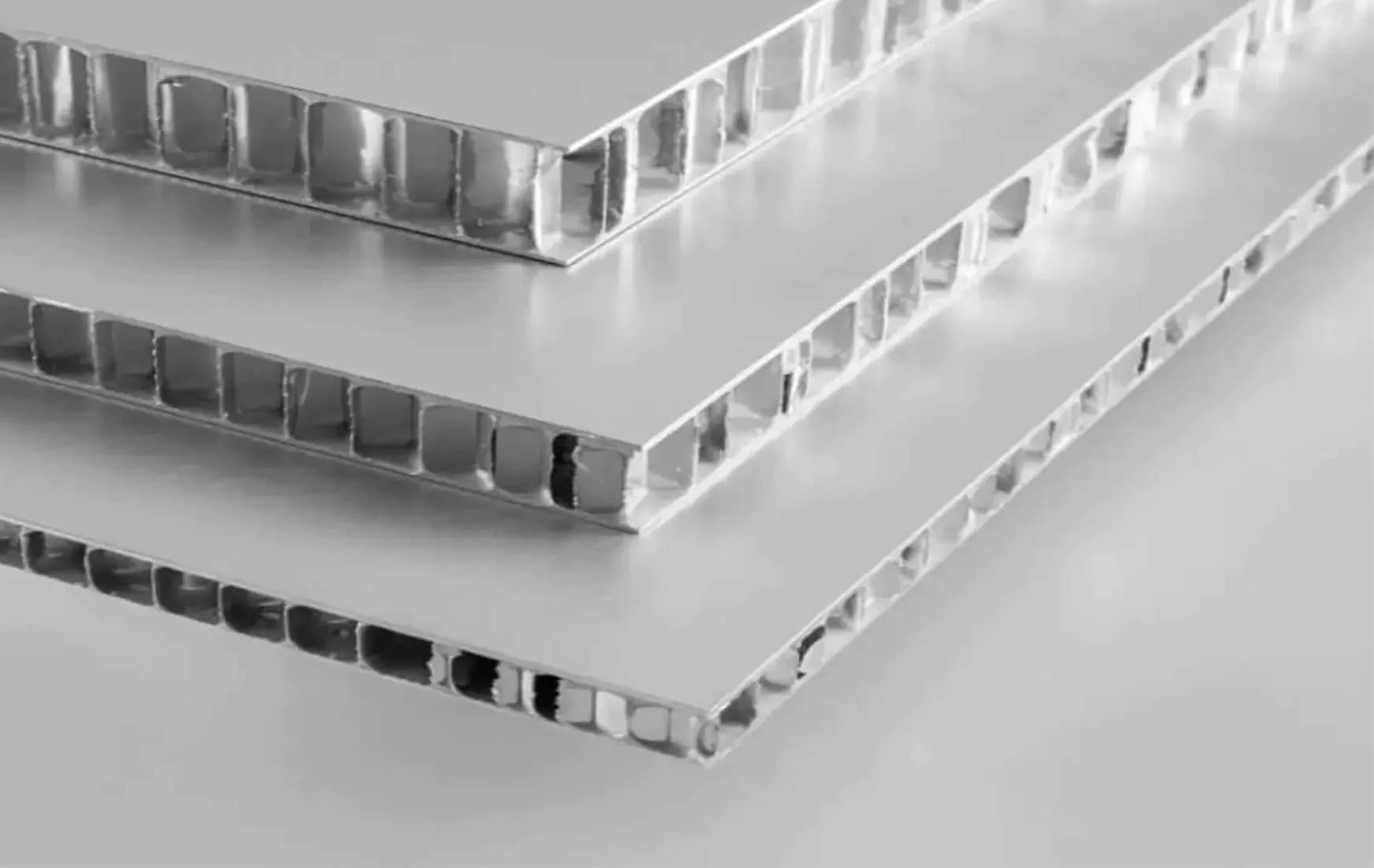

This versatility has led to their application in commercial complexes, transportation hubs, educational institutions, and residential towers. The ability to customize finishes — from metallic textures to matte surfaces — allows buildings to express unique visual identities while maintaining structural efficiency. 3D honeycomb composite panels and fire-resistant A2 panels are also being increasingly adopted in façade engineering for safety and design balance.

Structural Integrity and Fire Performance

Beyond visual and environmental advantages, aluminum composite materials also meet modern safety standards. Fire-resistant cores, such as those used in A2 composite panels, are designed to delay heat transfer and limit flame spread. These characteristics are vital for high-rise buildings, public facilities, and transportation terminals where safety requirements are strict.

Additionally, the bond strength between aluminum sheets and core materials ensures stability under mechanical stress. This property enhances the material’s resistance to impact and vibration, extending its service life in areas with high wind loads or heavy traffic. Engineers appreciate this combination of mechanical reliability and lightweight construction when designing large-scale curtain walls or roofing systems.

The Role of Aluminum Coil in Engineering Precision

Behind the production of high-performance composite panels lies the essential role of aluminum coil. The uniformity, coating precision, and mechanical stability of the coil directly affect the appearance and durability of the final product. Coated aluminum coils undergo rigorous quality control procedures — including surface inspection, thickness measurement, and adhesion testing — to meet engineering standards.

In architectural projects, these coils are used not only as a component of composite panels but also in cladding, roofing, and insulation systems. Their adaptability supports a broad range of construction applications, making them a fundamental material for builders seeking both functionality and modern aesthetics.

中文简体

中文简体 English

English Português

Português русский

русский Español

Español عربى

عربى